Want to learn more about the different ways you custom stickers and labels can be printed? Then this article is for you.

We cover different printing technologies as well as full colour printing and how to prepare your artwork for the best possible outcome.

Different types of print technology; an overview

There are many different ways to print self-adhesive stickers and labels. At Sticker it, we use the world's best digital printer to give you perfect results every time.

But there is much more to the world of custom printing.

Digital or traditional

The industry splits printers (aka presses) into two main categories; digital and traditional.

Digital printers use print-heads to apply multiple coloured inks, or toners, to a substrate (printable media) in one go. These presses usually print CMYK (cyan, yellow, magenta & black - more on that later), but sometimes this is increased to include white, orange, violet, green and others, so it's possible to print more colours.

Traditional printers tend to use printing plates or screens to apply a single colour at a time. They are extremely fast to print but also expensive to set up compared to digital because of the overhead to make a plate or screen.

Singles, sheets or rolls

Stickers & labels get printed onto sheets or long rolls (known as a web). The type of label sold will depend on the type of printer needed.

Here's an example of an industrial, narrow web, roll-to-roll printer:

And this is what a sheetfed press looks like:

You can also get wide-format roll-to-roll printers, which are typically for printing vehicle wraps:

Different types of digital printing

Here are some of the most used digital print methods:

-

Inkjet. Very popular, especially in wide-format printing. Ink can be solvent or water-based or cured by UV.

-

Dry toner. Used by companies like Xeikon, they print with dry powers & cure them rapidly using UV light.

-

Digital offset. Using a unique 'ElectroInk' formation developed by HP, the ink gets applied to a rubber blanket before being applied to the media, giving the ink time to wet out, resulting in an excellent result.

-

Thermal transfer. Ink gets printed on media through heat & pressure. A roll of ink on a PET carrier, usually made from a wax & resin mix, is melted by a print head, so the ink gets transferred to the media, creating an image.

Different types of traditional printing

Here are some of the most widely used traditional printing methods:

-

Offset. A plate gets chemically treated, so ink only sticks to the desired areas. The 'image' gets transferred to a blanket and then applied to the vinyl or paper media. This process gets repeated for all colours.

-

Screen printing. Ink gets transferred onto a substrate by being pushed through a mesh using a rubber squeegee. The mesh has a blocking stencil, so the ink gets transferred in the desired shape.

-

Flexo. A flexible plate wrapped around a roller applies the ink directly to the plastic or paper media. Modern printers are super-fast, printing up to 750m per minute.

Do you print in full colour?

Yes. We have the latest full-colour print technology to make your stickers look amazing.

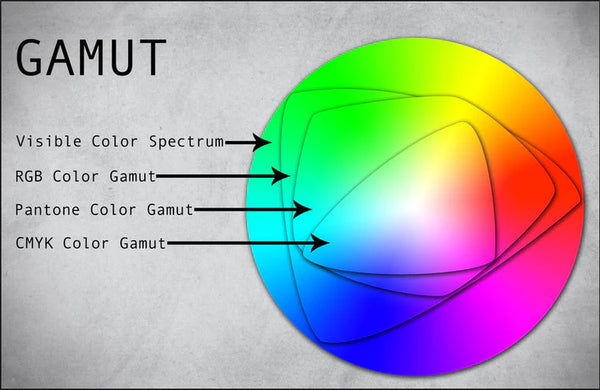

We print up to 8 colours at once to ensure we can get the widest possible colour gamut (this means we can get the best colour for you). More about that below.

Because we can print white, we can print onto transparent materials and back your design in white ink, so the colours are brilliantly vibrant. You can read more about printing white ink here.

CMYK vs RGB: What can and can't be printed

We used a lot of acronyms thus far. What do all these terms mean & how do they impact you? We'll explain all this & more in the next few minutes.

What is RGB?

RGB stands for Red, Green, Blue; three hues of light we can mix to create different colours.

16,777,216 colours, to be exact.

We mix between 0-255 units of each colour to create each RGB colour. RGB is an additive colour model, which means we add more colour to get to white. Like this:

See how it differs from CMYK colours, where the more ink we add, the closer to black we get.

RGB colour gamuts are used by things that use light to create colour - for example; computer screens and TVs.

What is CMYK?

CMYK stands for Cyan, Yellow, Magenta, and Black (key). We can mix these colours to create about 16,000 different colours.

CMYK is a subtractive colour model, which means we remove colour to get to white, as shown in the image above.

Many printers use CMYK along with white ink to create opacity when printing on clear vinyl. Some printers add other colours to these four basic colours to increase the colour gamut.

Three popular colours to add are; Orange, Violet & Green.

Here is an example of an orange printed in CMYK (right) vs the original (left). As you can see the CMYK colour isn't a good match and needs the additional orange in CMYKOVG to get a better match.

Pantone themselves says that CMYK printers can print 55% of Pantone spot colours, whereas CMYKOVG can print 90% of Pantone spot colours - this is a massive difference. (Source)

How does all this affect printing?

There are 16+ million RGB colours and only 16,000 CMYK colours, or a few hundred more if your printer prints CMYKOVG.

This image helps to show the differences in the colour gamut:

Here is a photo in CMYK and RGB side-by-side:

Designing on your computer that works in RGB can be risky because it gives us hundreds of beautiful vibrant colours that cannot be printed unless we get expensive spot colours made.

Your best bet is to design using CMYK colours to ensure you get the most accurate possible representation of the colour.

Wow, now you know everything there is to know about the world of sticker and label printing. If you need a little more help with finding the perfect sticker or label for you, you can:

- get custom samples printed to test your design on one of our materials

- take a closer look at each material by ordering a sample pack

- reach out to our customer service team

- or take our quiz to find your perfect material